Canada’s Leader For

Ground Improvement

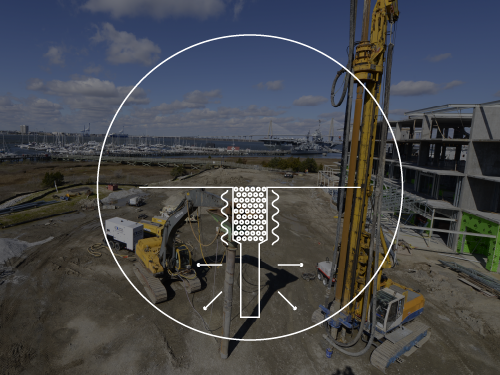

We’re here to help you, the contractor, developer, and engineer, to tame your most challenging soil types so that you can build your structural foundations exactly where you want to, no matter what the soil conditions are.

Offering you ground improvement solutions that are innovative, environmentally positive, and highly effective is what we do best.

Canada’s Leader For

Ground Improvement

We’re here to help you, the contractor, developer, and engineer, to tame your most challenging soil types so that you can build your structural foundations exactly where you want to, no matter what the soil conditions are.

Offering you ground improvement solutions that are innovative, environmentally positive, and highly effective is what we do best.

Sectors & Techniques

Menard Canada delivers a wide range of ground improvement techniques to provide our clients with the most economically sound solutions. Our expert regional team’s design, build and rehabilitate a wide range of structural foundations across Canada, helping our clients to simplify their projects, reduce their project costs, and to reduce project timelines with the very best in engineered foundation solutions. We invite you to explore the sectors we serve below and discover how we can help you make your next project better.

Sectors & Techniques

Menard Canada delivers a wide range of ground improvement techniques to provide our clients with the most economically sound solutions. Our expert regional team’s design, build and rehabilitate a wide range of structural foundations across Canada, helping our clients to simplify their projects, reduce their project costs, and to reduce project timelines with the very best in engineered foundation solutions. We invite you to explore the sectors we serve below and discover how we can help you make your next project better.

YOUR LOCAL CONTACT

Menard Canada has offices nationally to serve all regions effectively with a deep understanding of local soil conditions and challenges related to constructing foundations on challenging soil sites. With a local presence backed by Menard’s global expertise, you can be confident that we have the experience you need to ensure that your next project is a success.

Your local contact

Menard Canada has offices nationally to serve all regions effectively with a deep understanding of local soil conditions and challenges related to constructing foundations on challenging soil sites. With a local presence backed by Menard’s global expertise, you can be confident that we have the experience you need to ensure that your next project is a success.